Tuesday - 10 September

As I said last month, I would be busy for a few weeks with VW events, and I was. First there was a Klub VW Offroad trip out to Blackduck 4WD park near Gatton. Unfortunately the weather wasn't very good so all the soft buggy owners stayed home. So it was me, 2 other Baja's and Mike Sharp in his Buggy.

We had a brief play on some hills, before the others decided they liked playing in mud the most. I wasn't going to go in the mud because I couldn't be bothered cleaning it off. But after watching the others fail to make a certain mud run I got frustrated and had to show them how it's done. So I went and did it then parked the car again and continued watching the others, but now feeling satisfied instead of frustrated.

The next weekend was time to clean the mud off the car, and I was frustrated again. That mud was the most disgusting mud I have ever seen. I had to scrap it off the inside of my mud guards with a concrete chisel. It wouldn't hose off. I ended up spending most of the weekend trying to clean the car again.

The following weekend (last one) was the VW Action Day held by VWDCQ, and it is why I was trying to get my car clean. After a lot of work my car was finally clean again, and I won Best Baja at the show. So I think it was worth all the hard work.

So now I can get back to playing with the V6. During the other things in the last few weeks I did do a couple of small things on my half cut. I managed to remove the dashboard (difficult task) and have started trying to remove unnecessary wires from back there. It will definitely keep me busy.

Monday - 23 September

The last couple of weeks have been relatively productive. At night I sketched an 1800 flywheel, a 2lt flywheel and their respectively bell-housings. I then drew them in Cad in my spare time at work.

I cut the rear metal away from

behind the dash to make accessing the engine easier. I removed the power

steering pump and the 4WS power steering rack. In order to get the rack out I

cut away some more metal. Then to get at the power steering pump I cut away some

more metal, and before I know it there was no metal left around the engine. I

basically air chiselled the whole right hand side of the car off, then the left

hand side, then unbolted all the subframe etc until I was left with a bare

engine and gearbox sitting there (with wires and radiator

connected). Saved me having to hire an engine crane anyway ![]()

I continued removing unnecessary wires. There are heaps of the damn things. I would do it by finding something I didn't need, like blinkers or stereo, and then cutting the wires that led to that plug. It takes a while to follow and remove the whole wire sometimes. Every now and again I would connect the engine and make sure the engine still starts and everything I need still works.

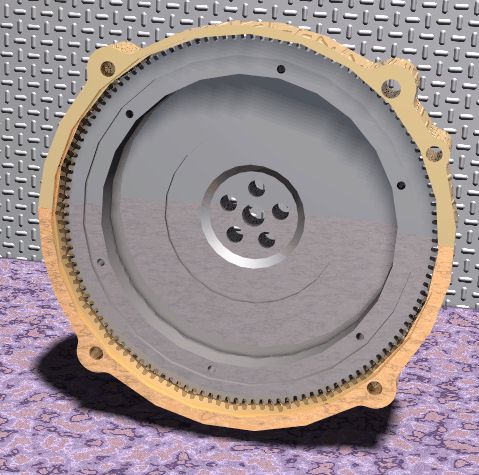

Yesterday I decided it was time to remove the gearbox so I can start drawing the V6 flywheel and engine bolt pattern so I can start designing the engine adaptor plate. I have noticed the V6 flywheel is too big to even fit in the VW bell-housing, but the clutch is about the same size as a 2lt VW clutch. So I think I might be able to machine the V6 ring gear off the V6 flywheel, and press a 2lt VW ring gear on. Then use either the V6 pressure plate with the VW clutch, or the drill and tap the V6 flywheel for the VW clutch and pressure plate.

Other

things of interest. The V6 clutch and friction faces looked very good so

it looks like the car hasn't been driven too hard. I changed the oil and

although it was black it didn't have any metal particles (phew). I quickly

measured the distance between the bottom of the sump and the crankshaft centreline.

It seems to be the same as a type 4 VW so I shouldn't have any ground clearance

problems even if I use the stock V6 sump.

| Distance between crankshaft centreline and bottom of the sump | |||

| Type 1 VW | Type 4 VW | KL-ZE V6 | WRX EJ20T |

| ~190 mm | ~200 mm | ~200 mm | ~280!!! mm |

The engine seems fairly light but I haven't been able to weigh it yet. I'm not sure how I will be able to do that. I will have to take some pictures of everything too.

Tuesday - 24 September

I measured up the V6 flywheel last night and drew it up today. The V6 flywheel uses a ball bearing input shaft support bearing. You can see in the picture below how the V6 flywheel is too big and won't fit in the VW bellhousing (the bellhousing is a transparent blue color).

So my plan is to machine the V6 ring gear off the flywheel and press a 2lt VW ring gear onto it, so it will look like the one in the pic below. The only problem is that to get the ring gear in the right spot for the starter I will probably have to press it onto the pressure plate pedestals instead of the solid part flywheel. I will have to think some more....